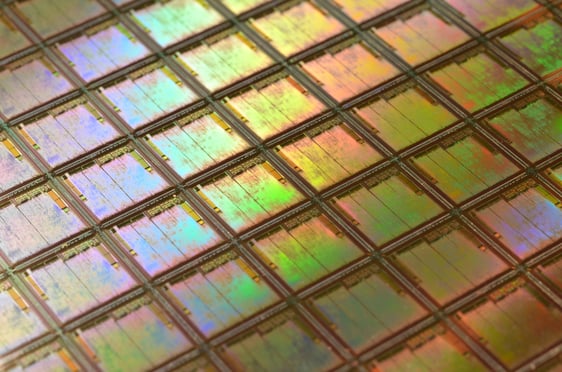

Semiconductor and Thin Films

Energetiq's light products are used in various semiconductor and thin-film manufacturing processes to enable the production of next generation devices and products.

EUV (Extreme Ultra-Violet) Lithography

As semiconductor device continue to shrink, the wavelength of light used in the photolithography process to print smaller patterns of 16 nm and below becomes critical. EUV lithography is a leading candidate for next generation lithography (NGL) because of its capability of printing these small features, covering the needs of the semiconductor industry well into the next decade.

Companies that are developing the EUVL (Extreme Ultra Violet Lithography) infrastructure need a reliable source of EUV light to test their products, such as mirrors, collection optics, and photoresist. In addition, there is a need for a light source for mask inspection at this nano-scale level. The Energetiq EQ-10R Series Electrodeless Z-Pinch™ EUV Sources provide highly reliable, cost-effective EUV light for the following applications:

EUV Mask Defect Inspection – Actinic inspection of EUV masks is a key technology that will enable the introduction of EUV lithography at 13.5 nm. Energetiq’s EUV products are the source of choice for mask blank inspection, aerial image inspection, and the development of patterned mask inspection. The high brightness and proven reliability and stability of Energetiq’s EQ-10R-HP are critical features for these applications.

EUV Resist Development – Resist performance is a critical technical issue on the path to making EUV lithography a viable approach for NGL. Resist manufacturers use Energetiq's EQ-10R sources to study both the sensitivity and outgassing of the photoresist.

EUV Optics Metrology – Optics for EUV are reflective and are comprise extremely complex multilayer coatings. The reflectivity and uniformity of the multilayer coating is critical to the wafer throughput and resolution of the scanner. Energetiq’s EQ-10R EUV sources are used by the world’s leading optical companies to test their optics prior to incorporation in wafer scanners. To simulate the requirements of high volume manufacturing (HVM) for EUVL, Energetiq offers the EQ-10-HR High Repetition Rate Electrodeless EUV Source that operates at a high pulse rate of 10 kHz.

LDLS for Wafer and other Thin-Film Applications

The LDLS Laser-Driven Light Source technology, embodied in the Energetiq EQ-99X and EQ-77, creates small, high brightness plasma that allows for efficient UV-Vis-NIR light collection for either broad spectral output or for specific narrow band spectral output, for use in:

On-Chamber monitoring of Thin-Film Etch and Deposition Processes – The high brightness and broad bandwidth of Energetiq’s EQ-99X and EQ-99X-FC LDLS products enable high performance monitoring of thin-film processes. The brightness allows the beam to be efficiently collimated across large process chambers, or focused to a small spot, thus assuring the highest possible signal for measurements. The broadband wavelength range from the deepest ultraviolet to the near infrared ensures high sensitivity across the widest range of thin film types.

193 nm and 248 nm Deep Ultraviolet (DUV) Photoresist Testing – A single Laser-Driven Light Source provides great flexibility and cost-effectiveness to the user. It covers multiple wavelengths and can be configured for narrow band spectral output for 193 nm or 248 nm photoresist testing, without the high costs associated with purchasing and operating excimer lasers.

Want to learn more about our semiconductor applications capabilities?