Laser-Driven Light Sources for Ellipsometry

Author: Mae Steinberg

Energetiq Technology, a wholly-owned subsidiary of Hamamatsu Photonics, is known for their innovative Laser-Driven Light Sources (LDLS™). LDLS products are used in many semiconductor applications including spectroscopic ellipsometry.

Introduction to Ellipsometry

Spectroscopic ellipsometry is a non-destructive metrology method used to examine nanoscale materials and is especially useful to determine the thickness of thin film substrates as well as quality monitoring and defect analysis. The technique dates to at least 1886 when the German physicist Paul Drude developed the fundamental equations and was first referred to by the term “ellipsometry” in 1945.

An ellipsometer measures the interaction of light with a sample material by measuring the change in polarization of reflected light. This technology can be used to measure multilayer film thickness, refractive index and absorption.

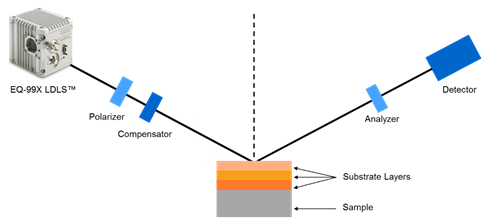

The main components of an ellipsometer are a collimated broadband light source such as Energetiq’s EQ-99X LDLS, a polarizer and an analyzer and detector pair as shown in Figure 1. Some ellipsometers also make use of a compensator to modify the polarization of the collimated light.

Figure 1: The main components of an ellipsometer are a light source, a polarizer and a detector. Some ellipsometers also make use of a compensator.

Ellipsometry Applications

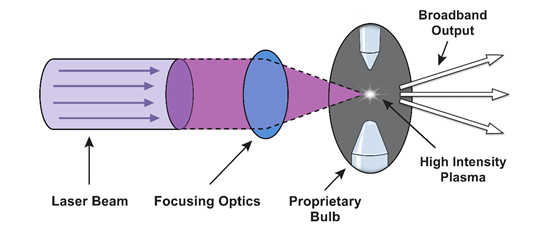

Energetiq’s innovative LDLS technology uses a CW laser to excite and sustain a very small xenon plasma thereby creating extremely bright, broadband light as shown in Figure 2. In traditional approaches such as with xenon arc and deuterium lamps, the brightness, spatial stability, and lamp lifetime are limited by the use of electrodes to couple power to the plasma. Energetiq’s LDLS technology allows for extremely stable light production for the duration of the lamp’s life because the laser provides all the energy to the plasma (the electrodes are used only during the very brief ignition).

Energetiq’s light sources are often used in spectroscopic ellipsometry for thin film characterization for the semiconductor industry. Ellipsometry has several other applications from research in physical sciences, to data storage solutions, flat panel display, biosensing, and optical coating on eye glasses. More recently, researchers in the medical field are beginning to use ellipsometry to examine biological samples.

A Superior Light Source

Energetiq’s Laser-Driven Light Sources are ideal for ellipsometry because of their extremely high brightness, broad emission spectrum and very small spot size. Other commonly used ellipsometer light sources include solid-state lasers, traditional xenon or mercury arc lamps.

For a high-volume production application that calls for maximum throughput like many processes in semiconductor manufacturing, brightness becomes a very important factor in selecting a light source. Brightness describes the ability of a light source to efficiently couple photons into a small area. In semiconductor manufacturing, for example, delivering more photons per second means more measurements per second, i.e. higher production throughput.

The LDLS offers an advantage in brightness across a broad spectral range and is ideal for nanoscale applications because it offers an unparalleled number of photons from a xenon plasma spot as small as 100 µm in diameter. Because the light is coming from such a small spot, the broadband output can be very efficiently coupled into many optical systems with small étendues.

The LDLS becomes even more appealing when you consider its broad wavelength range. The LDLS offers extremely high brightness across the UV-Vis-NIR range of the electromagnetic spectrum from 170 nm to 2,400 nm. This is relevant because, depending on the material properties of the sample being examined, and its thickness, different wavelengths are optimal. Using an LDLS, an ellipsometer can simultaneously provide information about multiple material properties at once. For ellipsometers using a monochromatic laser light source, the user is limited to the particular wavelength, and multiple lasers may be needed to unlock information from the measured sample. With the LDLS, an ellipsometer can be marketed for multiple applications. For instance, semiconductor manufacturing with very thin layers requires deep ultraviolet wavelengths, but flat panel display quality control requires visible light.

LDLS Principle of Operation

Energetiq’s innovative LDLS technology uses a CW laser to excite and sustain a very small xenon plasma thereby creating extremely bright, broadband light as shown in Figure 2. In traditional approaches such as with xenon arc and deuterium lamps, the brightness, spatial stability, and lamp lifetime are limited by the use of electrodes to couple power to the plasma. Energetiq’s LDLS technology allows for extremely stable light production for the duration of the lamp’s life because the laser provides all the energy to the plasma (the electrodes are used only during the very brief ignition).

Conclusion

Spectroscopic ellipsometers are essential tools for thin film characterization, among a number of other applications. Laser-Driven Light Sources offer many advantages when compared to other light sources used in ellipsometry applications. The unique principle of operation maximizes the lifetime and ensures high spatial stability enabling high throughput measurements in production environments. The extremely high brightness and broad wavelength range increase the flexibility of an ellipsometer by removing any barriers presented by a limited wavelength range, ideal for laboratory or other multi-use or research settings. For the most accurate and precise measurements, a broadband source like those from Energetiq unlocks new possibilities in spectroscopic ellipsometry.

References

1. https://www.sciencedirect.com/topics/chemistry/ellipsometry

2. Arwin, H.. (2011). Application of ellipsometry techniques to biological materials. Thin Solid Films. 519. 2589-2592. 10.1016/j.

tsf.2010.11.082.

3. https://www.energetiq.com/technote-understanding-radiance-brightness-irradiance-radiant-flux

4. https://semilab.com/category/products/spectroscopic-ellipsometry

5. Hilfiker, J.N., Synowicki, R.A., Hale, J.S. and Bungay, C. (1998), Characterizing Thin Films in the Flat Panel Display Industry

with Variable Angle Spectroscopic Ellipsometry (VASE®). SID Symposium Digest of Technical Papers, 29: 491-494.

doi:10.1889/1.1833800